The Rise of 3D Printing in Jewelry: A Revolution in Design and Production

Related Articles: The Rise of 3D Printing in Jewelry: A Revolution in Design and Production

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Rise of 3D Printing in Jewelry: A Revolution in Design and Production. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Rise of 3D Printing in Jewelry: A Revolution in Design and Production

The jewelry industry, historically known for its meticulous craftsmanship and reliance on traditional techniques, is undergoing a significant transformation. This revolution is fueled by the emergence of 3D printing, a technology that empowers designers and manufacturers to create intricate and personalized jewelry with unprecedented speed and precision. This article delves into the intricacies of 3D printing in jewelry, exploring its functionalities, benefits, and the impact it has on the industry’s future.

Understanding the Essence of 3D Printing in Jewelry

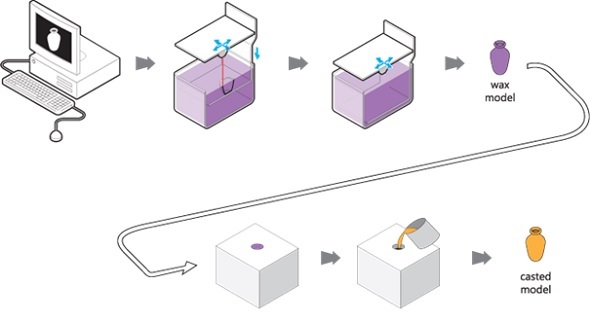

3D printing, also known as additive manufacturing, is a process that constructs three-dimensional objects layer by layer from a digital design. This technology utilizes specialized materials, such as wax, resin, or metals, which are selectively solidified by a controlled energy source, forming intricate shapes with exceptional detail.

In the context of jewelry, 3D printing offers a revolutionary approach to design and production. It allows for the creation of complex and highly customized pieces, pushing the boundaries of traditional craftsmanship. This versatility empowers designers to translate their imaginative concepts into tangible reality, while manufacturers gain the flexibility to cater to individual preferences and market demands.

Benefits of 3D Printing in Jewelry

The adoption of 3D printing in jewelry brings a multitude of advantages, transforming the industry landscape in several key areas:

1. Design Freedom and Innovation:

3D printing liberates designers from the constraints of traditional techniques. Complex geometries, intricate details, and unconventional shapes become readily achievable, allowing for the creation of truly unique and aesthetically captivating pieces. This empowers designers to explore their creative vision without limitations, resulting in a wider array of innovative and groundbreaking jewelry designs.

2. Enhanced Customization and Personalization:

The ability to print intricate designs on demand enables the creation of personalized jewelry tailored to individual tastes and preferences. Customers can collaborate with designers to create bespoke pieces that reflect their unique style and story, fostering a deeper connection with their jewelry. This personalized approach caters to the increasing demand for customized products in today’s market.

3. Rapid Prototyping and Reduced Lead Times:

3D printing significantly reduces the time required for prototyping and production. Designers can quickly iterate their designs, experimenting with different shapes and materials before committing to final production. This rapid prototyping capability accelerates the design process, allowing for quicker product launches and increased market responsiveness.

4. Cost-Effectiveness and Efficiency:

3D printing can be a cost-effective solution for jewelry production, particularly for small-scale batches and customized pieces. It eliminates the need for expensive molds and tooling, which are traditionally required for traditional manufacturing methods. This efficiency translates to lower production costs, making high-quality jewelry accessible to a wider audience.

5. Reduced Waste and Sustainability:

3D printing promotes a more sustainable approach to jewelry production. By creating only the necessary material, it reduces waste compared to traditional methods that often involve material loss during the manufacturing process. This environmental consciousness aligns with the growing demand for sustainable practices in various industries.

The Impact of 3D Printing on the Jewelry Industry

The integration of 3D printing into the jewelry industry is having a profound impact, shaping its future trajectory:

1. Democratization of Design and Production:

3D printing empowers independent designers and small businesses to enter the jewelry market. It eliminates the high entry barriers associated with traditional manufacturing methods, fostering a more inclusive and competitive landscape. This democratization of design and production enables a wider range of creative voices to contribute to the industry.

2. Expansion of Design Possibilities:

3D printing opens up new avenues for design exploration, pushing the boundaries of what is possible in jewelry creation. Intricate details, complex geometries, and unconventional shapes become readily achievable, allowing for the creation of pieces that defy traditional limitations. This expansion of design possibilities fuels a renaissance of creativity and innovation within the industry.

3. Increased Consumer Demand for Customized Jewelry:

The ability to create personalized jewelry through 3D printing has fueled a growing consumer demand for customized pieces. Customers seek jewelry that reflects their unique style and tells their personal stories. This shift in consumer preferences is driving innovation and growth within the industry, as businesses adapt to meet this demand.

4. New Business Models and Collaboration:

3D printing is fostering the emergence of new business models and collaborative partnerships within the jewelry industry. Designers, manufacturers, and retailers are finding innovative ways to leverage this technology to create unique offerings and cater to evolving consumer demands. This collaborative spirit is driving innovation and growth across the value chain.

5. Evolution of Traditional Jewelry Techniques:

While 3D printing offers a revolutionary approach, it does not replace traditional jewelry techniques entirely. Instead, it complements and enhances them, allowing for the creation of hybrid pieces that combine the precision of 3D printing with the artistry of handcrafting. This synergy creates a richer and more diverse jewelry landscape.

FAQs about Jewelry 3D Printing Services

1. What types of jewelry can be 3D printed?

3D printing can be used to create a wide range of jewelry, including:

- Rings: From simple bands to intricate designs with gemstones.

- Earrings: Studs, drop earrings, and even complex chandelier designs.

- Necklaces: Pendants, chains, and statement pieces with intricate details.

- Bracelets: Cuff bracelets, chain bracelets, and bangles with unique patterns.

- Brooches: Decorative brooches with intricate designs and textures.

2. What materials can be used for 3D printed jewelry?

Common materials used for 3D printed jewelry include:

- Wax: Used for lost wax casting, where the printed wax model is used to create a mold for casting in metal.

- Resin: Offers a wide range of colors and finishes, suitable for creating intricate designs.

- Metals: 3D printing with metals like gold, silver, and platinum is becoming increasingly popular, allowing for the creation of high-quality jewelry.

3. How much does 3D printed jewelry cost?

The cost of 3D printed jewelry varies depending on factors such as the complexity of the design, the materials used, and the size of the piece. However, 3D printing can be a cost-effective option, especially for smaller batches and personalized designs.

4. How long does it take to 3D print jewelry?

The printing time depends on the size and complexity of the design. Simple pieces can be printed within a few hours, while more intricate designs may take several days.

5. Is 3D printed jewelry durable?

The durability of 3D printed jewelry depends on the material used. Resin jewelry is generally less durable than metal jewelry. However, advancements in 3D printing technology are leading to the development of more durable and long-lasting materials.

Tips for Choosing a Jewelry 3D Printing Service

When choosing a jewelry 3D printing service, consider the following factors:

- Experience and Expertise: Look for a service with experience in jewelry 3D printing and a proven track record of quality.

- Material Options: Ensure the service offers a range of materials suitable for your design requirements.

- Design Capabilities: The service should have the capability to handle complex designs and intricate details.

- Customer Service: Choose a service with responsive customer support and a clear communication process.

- Pricing and Turnaround Time: Consider the pricing structure and turnaround times to ensure they align with your budget and timeline.

Conclusion

3D printing has revolutionized the jewelry industry, offering unprecedented design freedom, personalization, and efficiency. This technology empowers designers to push creative boundaries, while manufacturers gain the flexibility to cater to individual preferences and market demands. As 3D printing continues to evolve, it is poised to play an increasingly significant role in shaping the future of jewelry, fostering a more innovative, sustainable, and accessible industry for both creators and consumers.

Closure

Thus, we hope this article has provided valuable insights into The Rise of 3D Printing in Jewelry: A Revolution in Design and Production. We appreciate your attention to our article. See you in our next article!