The Rise of Precision: Jewelry 3D Scanners Revolutionizing Design and Production

Related Articles: The Rise of Precision: Jewelry 3D Scanners Revolutionizing Design and Production

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Rise of Precision: Jewelry 3D Scanners Revolutionizing Design and Production. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Rise of Precision: Jewelry 3D Scanners Revolutionizing Design and Production

The jewelry industry, long steeped in tradition and meticulous craftsmanship, is undergoing a significant transformation. At the forefront of this evolution stands the 3D scanner, a technological marvel that is revolutionizing design, production, and even the way we interact with jewelry.

Unveiling the Power of 3D Scanning in Jewelry

A 3D scanner, in essence, is a device that captures the three-dimensional shape of an object, translating it into a digital representation. In the jewelry world, this technology offers a plethora of benefits, impacting every stage of the jewelry lifecycle, from initial design to final production.

1. Design and Prototyping: A Leap Forward in Creativity

- Conceptualization Made Easy: 3D scanners empower designers to translate their creative visions into tangible models with unprecedented speed and accuracy. They can scan existing jewelry pieces, organic forms, or even their own hands to create unique designs.

- Iterative Design: Exploring Possibilities: The digital nature of 3D scans allows for rapid prototyping and experimentation. Designers can effortlessly modify and refine their designs, exploring various iterations before committing to a final product.

- Virtual Mockups: A Realistic Preview: 3D scanners enable the creation of virtual mockups, providing a realistic representation of the final jewelry piece. This allows clients to visualize the design before production, ensuring satisfaction and minimizing potential revisions.

2. Production: Efficiency and Precision Redefined

- Automated Production: Streamlining the Process: 3D scanners are the cornerstone of automated jewelry production. By generating precise digital models, they facilitate the use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems. This allows for automated processes like 3D printing, casting, and engraving, leading to increased efficiency and reduced production time.

- Customization Made Accessible: 3D scanning empowers jewelers to offer personalized jewelry solutions with ease. Clients can have their own unique designs captured and reproduced, leading to a more bespoke and intimate experience.

- Mass Customization: Meeting Diverse Needs: 3D scanners enable the creation of customized jewelry on a larger scale. This opens up opportunities for mass customization, where individual preferences are incorporated into mass-produced designs.

3. Quality Control: Ensuring Excellence at Every Step

- Precision Measurement: A Foundation for Accuracy: 3D scanners provide precise measurements of every detail of a jewelry piece, ensuring consistency and accuracy in production. This eliminates the potential for human error and guarantees the highest quality standards.

- Detection of Imperfections: Uncovering Hidden Flaws: 3D scanners can identify even the most subtle imperfections in jewelry pieces, allowing for corrective measures before production or during quality control checks. This ensures that only flawless pieces reach the customer.

4. Inventory Management: Streamlining Operations

- Digital Catalogs: A Comprehensive Database: 3D scanners allow jewelers to create digital catalogs of their entire inventory. This allows for easy access to detailed information about each piece, simplifying inventory management and sales processes.

- Virtual Showrooms: Expanding Reach: Digital catalogs created from 3D scans can be used to create virtual showrooms, enabling customers to browse and purchase jewelry from anywhere in the world. This expands the reach of jewelers and opens up new markets.

5. Reverse Engineering: Reimagining the Past

- Preserving Heritage: Capturing History: 3D scanners play a crucial role in preserving historical jewelry pieces. By capturing their intricate details, they create digital records that can be used for restoration, replication, or simply for educational purposes.

- Inspiration from the Past: Modernizing Traditions: 3D scans of antique jewelry pieces provide designers with a wealth of inspiration. They can analyze the details, techniques, and styles of past eras to create modern interpretations that pay homage to history.

Types of Jewelry 3D Scanners: Navigating the Options

The world of 3D scanners offers a diverse range of options, each catering to specific needs and applications within the jewelry industry. Here’s a breakdown of the most common types:

1. Structured Light Scanners:

- Principle of Operation: These scanners project a pattern of light onto the object, capturing the distorted pattern reflected back. This information is then used to reconstruct the 3D shape.

- Strengths: Relatively affordable, offer high accuracy and resolution, suitable for scanning intricate details.

- Limitations: May require controlled lighting conditions, not ideal for scanning large or complex objects.

2. Laser Scanners:

- Principle of Operation: Employ a laser beam to measure the distance to points on the object’s surface. These measurements are then compiled to create a 3D model.

- Strengths: Offer high accuracy and precision, suitable for scanning large and complex objects.

- Limitations: Can be expensive, require specialized calibration and maintenance.

3. Time-of-Flight Scanners:

- Principle of Operation: Emit a pulse of light and measure the time it takes to return from the object’s surface. This information is used to calculate the distance and create a 3D model.

- Strengths: Relatively fast scanning speed, suitable for scanning moving objects.

- Limitations: May have lower accuracy compared to other methods, not ideal for capturing intricate details.

4. Photogrammetry Scanners:

- Principle of Operation: Capture multiple images of the object from different angles. These images are then processed to create a 3D model using computer vision techniques.

- Strengths: Affordable, easy to use, suitable for scanning large and complex objects.

- Limitations: May require a controlled environment with good lighting, not as accurate as other methods.

Choosing the Right 3D Scanner: A Practical Guide

Selecting the right 3D scanner for your jewelry business requires careful consideration of several factors:

- Budget: Scanners vary significantly in price, ranging from affordable handheld models to expensive industrial-grade systems.

- Accuracy and Resolution: The level of accuracy and resolution needed depends on the specific application. For fine jewelry, high accuracy is crucial, while for larger pieces, a lower resolution may suffice.

- Scanning Range: The scanning range determines the size of objects that can be scanned. Consider the typical size of jewelry pieces you work with.

- Scanning Speed: The scanning speed is important for high-volume production or when scanning multiple pieces.

- Software Compatibility: Ensure that the scanner is compatible with the software you intend to use for design, modeling, and production.

FAQs: Addressing Common Concerns

1. What is the accuracy of a jewelry 3D scanner?

The accuracy of a jewelry 3D scanner varies depending on the type and model. High-end scanners can achieve accuracies of up to 0.01 mm, while lower-end models may have accuracies of 0.1 mm or more.

2. Can I scan any type of jewelry?

Most 3D scanners can scan a wide variety of jewelry materials, including metals, gemstones, plastics, and ceramics. However, it’s important to check the scanner’s specifications for compatibility.

3. How do I prepare jewelry for scanning?

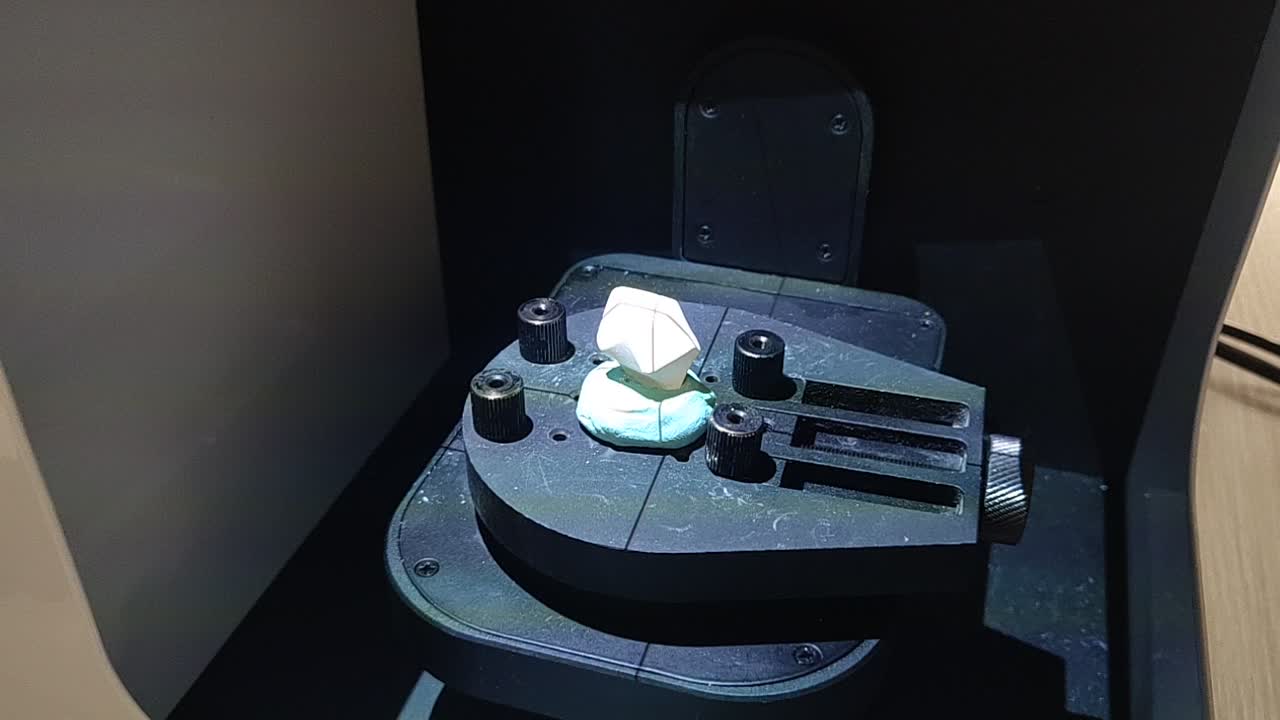

Before scanning, jewelry should be cleaned and polished to remove any dirt or debris that could interfere with the scan. It’s also helpful to place the jewelry on a non-reflective surface.

4. What software do I need to use with a jewelry 3D scanner?

There are various software programs available for processing and manipulating 3D scans. Some popular options include MeshLab, Blender, and Rhino.

5. Are jewelry 3D scanners expensive?

The cost of jewelry 3D scanners can vary widely. Entry-level models can be purchased for a few hundred dollars, while professional-grade scanners can cost tens of thousands of dollars.

Tips for Effective Jewelry 3D Scanning:

- Optimize Lighting: Ensure adequate lighting conditions for accurate scanning. Use a combination of natural and artificial light to minimize shadows and reflections.

- Clean the Jewelry: Remove any dirt, debris, or fingerprints from the jewelry surface before scanning.

- Use a Stable Platform: Place the jewelry on a stable and non-reflective surface to prevent movement during scanning.

- Calibrate the Scanner: Regularly calibrate the scanner to ensure accurate measurements.

- Experiment with Settings: Adjust scanning settings like resolution, scan speed, and lighting to achieve optimal results.

- Post-Processing: Utilize software to clean up the scan data, remove noise, and optimize the model for 3D printing or other applications.

Conclusion: Embracing the Future of Jewelry

The emergence of 3D scanning technology marks a pivotal moment in the history of jewelry. By offering unparalleled precision, efficiency, and creative possibilities, 3D scanners are empowering jewelers to redefine the industry’s landscape. From bespoke creations to mass customization, the future of jewelry is being shaped by this transformative technology, ushering in an era of innovation and personalized luxury.

Closure

Thus, we hope this article has provided valuable insights into The Rise of Precision: Jewelry 3D Scanners Revolutionizing Design and Production. We thank you for taking the time to read this article. See you in our next article!